Company > About us

History

MBR TECHNOLOGY, located in Civitella del Tronto (TE) with its 1,300 square meters for production departments and office building, has been operating for over 10 years in various mechanical sectors.

In 2004 the two founding partners Bacà Davide and Raschiatore Mauro join their know-how to give life to MBR Technology, whose name contains the initials of the members themselves.

MBR Technology alias Mechanical Technology Bacà and Raschiatore can boast over 30 years of experience of the partner Raschiatore as a small workshop for lathing, milling, carpentry and industrial revisions. The contribution of the partner Bacà Davide consists in the use, for over 25 years, of the CAD CAM systems (ME10, AUTOCAD, CATIAV5, SURFCAM), Head of the technical office and quality system in companies similar to ours and five years of experience at the multinational Swedish SECO TOOLS SPA as a sales engineer for some provinces of the Abruzzo and Marche regions. From the aforementioned period we get the knowledge of the most innovative techniques concerning the removal of shavings and tooling systems of the most varied processes as well as the knowledge of various materials up to modern super alloys and aerospace materials.

Sectors of interest

We are able to respond promptly to the realization of works that go from the single detail to complex groups containing many codes.

We have a technical office able to extract directly from the overall drawings the details that compose it and prepare them for the realization through 2D and 3D CAD workstations and CAM stations directly connected to the workshop.

We produce stainless steel casings for components of industrial machinery. We build molds and wheels complete with training for the cellulose transformation sector.

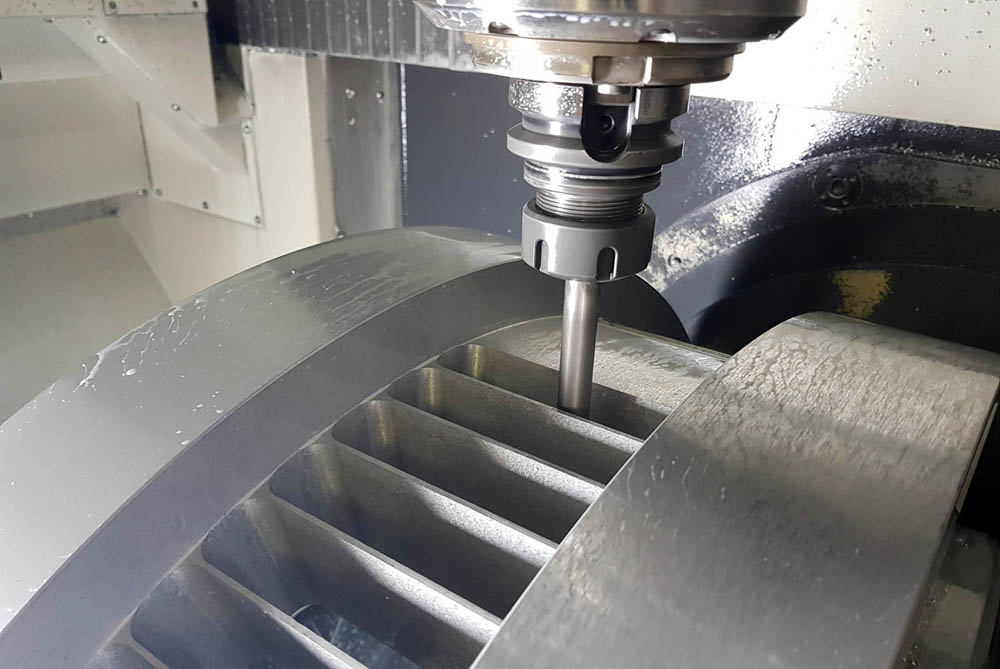

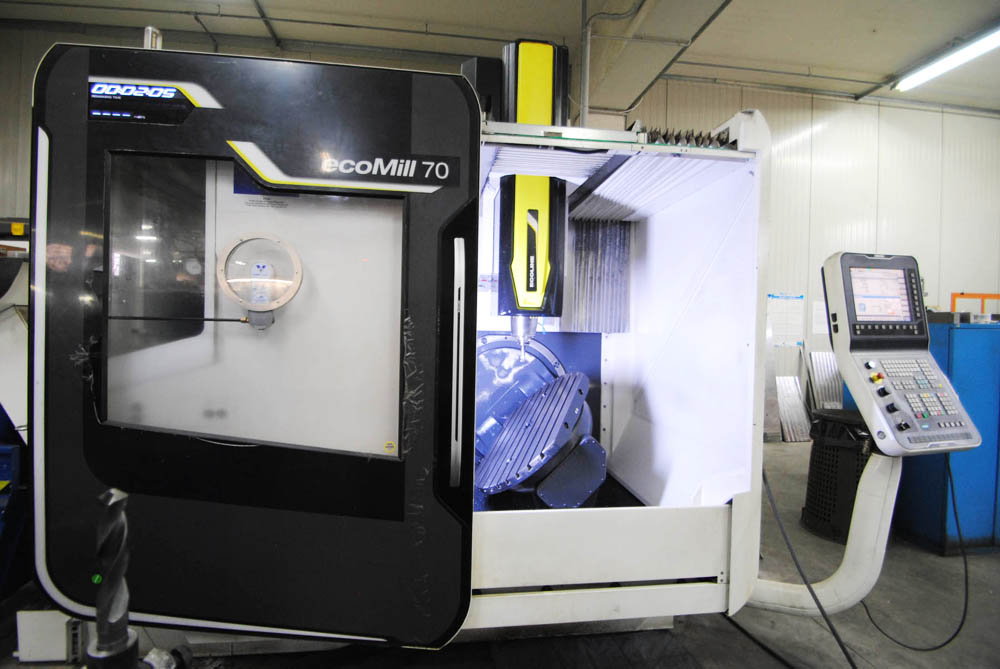

Among other things we deal with medium-small carpentry with dedicated equipment (water cutting, CNC bending machines, calenders, welding machines, etc.), machined carpentry, turning, wheel grinding, milling with 5X machining centers, machining of INOX casings, possibility assembly of complete groups and also of spare parts on sample.

We have a wide range of stainless steel and aluminum sheets to be cut at the WaterJet up to 60 mm, well stocked on appropriate external and internal warehouses. We also have an assortment of polycarbonate sheets (LEXAN) up to 12 mm thick to be cut at the WaterJet.